You may have had problems with glass cracking on tables, windows, and the like.

This can be caused by a rock hitting or placing an object on a glass table.

Today we are going to teach you how to fix cracked glass.

The museum is located in the western part of Los Angeles’ Exposition Park opposite the University of Southern California.

In honor of the creator of the Star Wars series, the museum is named after the famous American filmmaker George Lucas.

According to previous announcements, the museum is set to become a recreational and cultural complex, including the Los Angeles Museum of Natural History, the California Science Center and the Los Angeles Theater.

In 2014, an international design competition was held to create a creative and innovative structure for the Lucas Museum.

Inspired by the image of a spaceship, the Chinese company MAD Architecture was able to win this attractive competition.

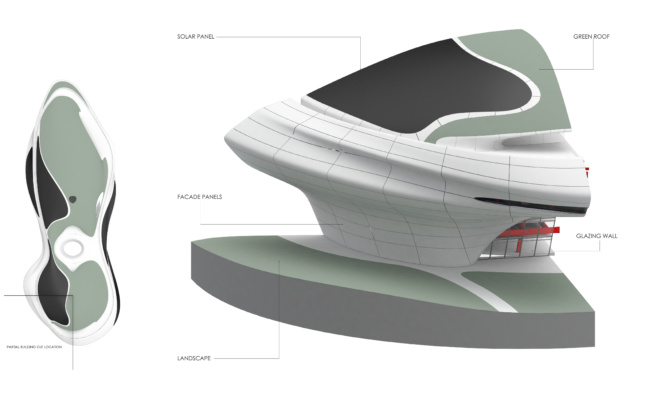

Lucas Museum with GFRP view

The massive building is housed on a bas-relief system that shakes the structure slowly in the event of an earthquake.

In this regard, in order for the system to work properly, the design team must pay special attention to the weight of the outer panel or the top plate of the structure.

The museum was originally intended to use glass fiber-reinforced concrete (GFRC).

These raw materials are a prominent composite material among architects for the construction of curved structures.

The use of these materials put a lot of pressure on the basic insulation system and structure.

That’s why the design team used fiberglass-reinforced plastic (GFRP), a durable, lightweight composite material.

Other explanations

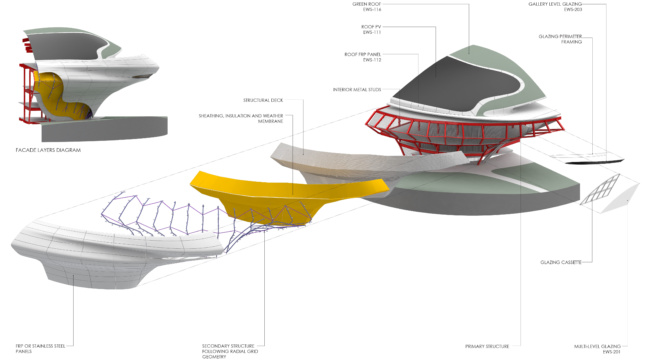

The main advantage of both composites is the extremely smooth outer surface.

If the panels are installed correctly, you can benefit from this smooth surface.

Tools such as Maya, Rhino, Dynamo and Revit have been used in the design of this spaceship.

All modeling information was sent to Kreysler & Associates in Northern California for construction.

Kreysler & Associates has implemented all 1,500 GFRP components.

In this company, all foam molds are cut by CNC machine.

The installation of these panels is scheduled to begin in the second half of next month.

The Lucas Museum is currently halfway there.

Source archpaper

Bohle Group expands its selection of surface finishes for the FrameTec Select 2.0 glass partitioning system by a powder-coated, matt black (RAL 9005). The system stands out thanks to its flexible installation options with a single door, overpanel or sidelight following the industrial design trend, which is marked by black, metallic elements.

Glass Partitioning System

FrameTec Select 2.0 does not only convince thanks to its high-quality processing but also excels due to its fast and cost-efficient installation. The retainer profiles are inserted into the multi-functional running track and the hinges are subsequently fixed with two screws. Stable corner connectors for frame and glazing profiles make the installation as easy and safe as can be.

FrameTec Select 2.0 appeals through the unobtrusive, uniform appearance of the whole system. Frame and glazing profiles have the same, low depth of 36.5 mm and therefore provide a straight-lined design, which conveys a particularly harmonious and lightweight appearance.

FrameTec Select 2.0 – a stylish system with many benefits:

- Numerous, flexible installation options

- Unobtrusive, uniform appearance

- Fast and cost-effective installation

- The narrow multi-functional running track is tightly covered by the clip-on profile.

- High-quality workmanship

- Dry glazing with plug-in sealing strips

- Pre-assembled sets – can be trimmed to size

source glassweb